Fibrous glass duct system

The fibrous glass duct system is used to conserve heating and cooling energy and to control duct-borne noise in commercial, institutional, or residential heating, ventilating, and air-conditioning ductwork operating in the range of + 2 in. w.g. (+ 500 Pa) static pressure, up to at least 5,000 fpm (25.4 m/sec) internal air velocity, and internal air temperature between 40˚F (4˚C) and 250˚F (121˚C). Ducts are only for indoor use and should be located in areas where ambient temperature does not exceed 150˚F (66˚C).

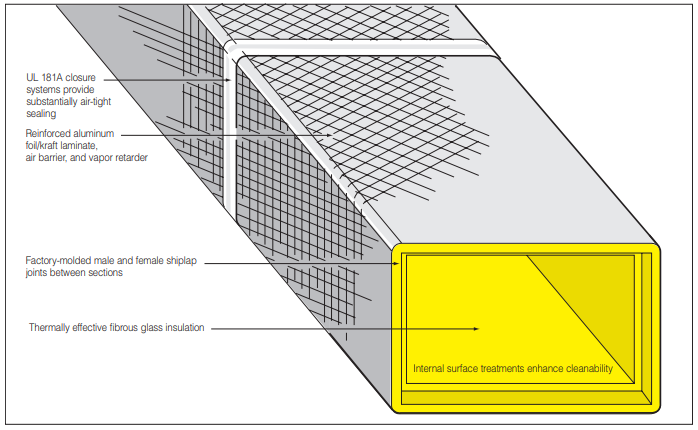

The fibrous glass duct system is normally made up of nominal four foot (1.2m) modules fabricated from 1, 11/2, or 2 in. (25, 38, or 51mm) thick, flat fibrous glass duct board stock having a factory-applied reinforced aluminum exterior air barrier finish. Duct system modules are fabricated using either specially designed hand tools or grooving and closure machines. Duct fittings such as tees, offsets, elbows, and transitions are also fabricated from these modules or from flat duct board stock.

Duct board products are available with coated or faced airstream surfaces. These products permit rigorous cleaning of the duct surface where dust has been allowed to collect in the duct due to lack of filtration or poor maintenance. Additionally, some of these products have higher maximum velocity ratings.

Duct systems fabricated from fibrous glass duct board products qualify under UL 181 as Class 1 Air Ducts, meeting the fire safety requirements of NFPA 90A and 90B including limited combustibility. They also comply with all widely used model codes. Duct board joint closures are sealed using one of three UL 181A listed systems.