Installation

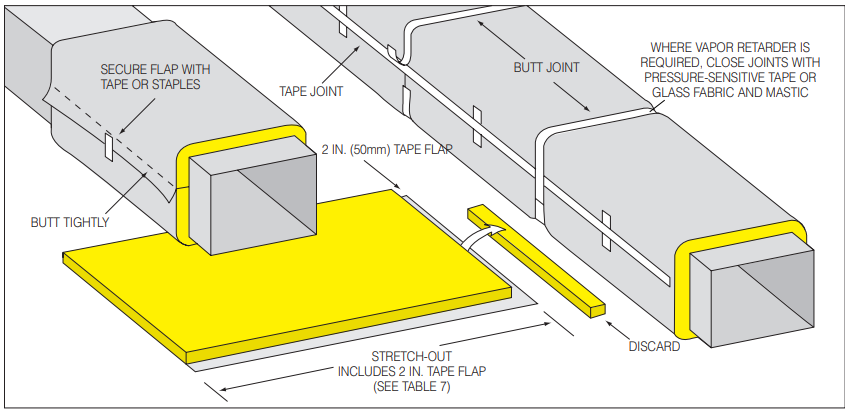

Fibrous glass duct wrap insulations are installed with facings away from the duct surface. See Figure 22. A stapling flap, prepared at the time of installation, overlapping the insulation and facing at the other end of the piece of duct wrap, is stapled to form a longitudinal seam. Where a vapor retarder is required, the seam is sealed with pressure-sensitive tape. Adjoining duct wrap sections are similarly stapled and sealed using the facing flap on one edge of the duct wrap as produced at the factory. Seams and joints may also be sealed with mastic and glass fiber fabric. For complete installation details, consult manufacturers or National Commercial and Industrial Insulation Standards, 1999, 5th Edition, Midwest Insulation Contractors Association (MICA).

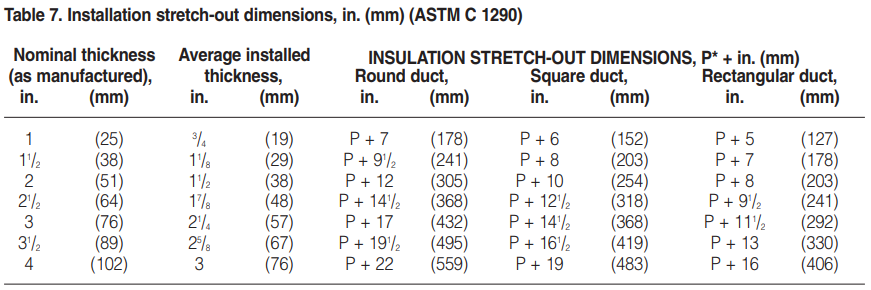

Dimensions in Table 7 are established by ASTM C 1290 and should be used when cutting duct wrap insulation so that, once installed, it is not compressed to less than 75% of nominal (out-of-package) thickness.