Value Versatility Speaks Volumes

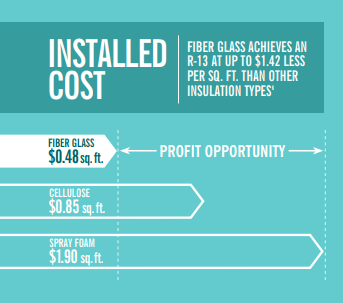

Overall project value is a critical need for today's contractors and their builder clients. Fiber glass not only achieves an R-13 at up to $1.42 less per sq. ft. than other insulation types7 it enables shorter installation time and provides a wide range of products.

IBP President of External Affairs Jeff Hire explains, "Fiber glass continues to be a great high-performance and cost-effective product for our projects, especially in the entry-level home building market, and in the multi-family housing space." Hire says. "Even some custom home builders recognize the flexibility and performance fiber glass can offer for their unique designs."

Wisconsin Insulation Services, President, John Ratzow sees fiber glass performance and costs favorably when compared to spray foam. "Spray foam is significantly more costly than fiber glass to get the same performance. Fiber glass is our product of choice because it is time tested, cost effective and can meet any performance level for our builders."

Ratzow explains that 95+% of the walls they fit include fiber glass batts. Of that 95%, probably 82 - 83% are R-21 batts. "Virtually all of the walls are 2 x 6 construction, driven by the emerging trend around energy efficiency" he notes.

Dean Moody concurs. ""Spray foam is much more expensive than fiber glass. Fiber glass is our product of choice, we use fiber glass nearly 99% of the time on homes we insulate."