Entry: Go/No-Go Decision Making

|

Go/No-Go Decision Making: A decision model for tactical advance within a structure based on data and evidence rather than opinion. This decision model requires the use of an NFPA 1301-compliant thermal imaging camera. |

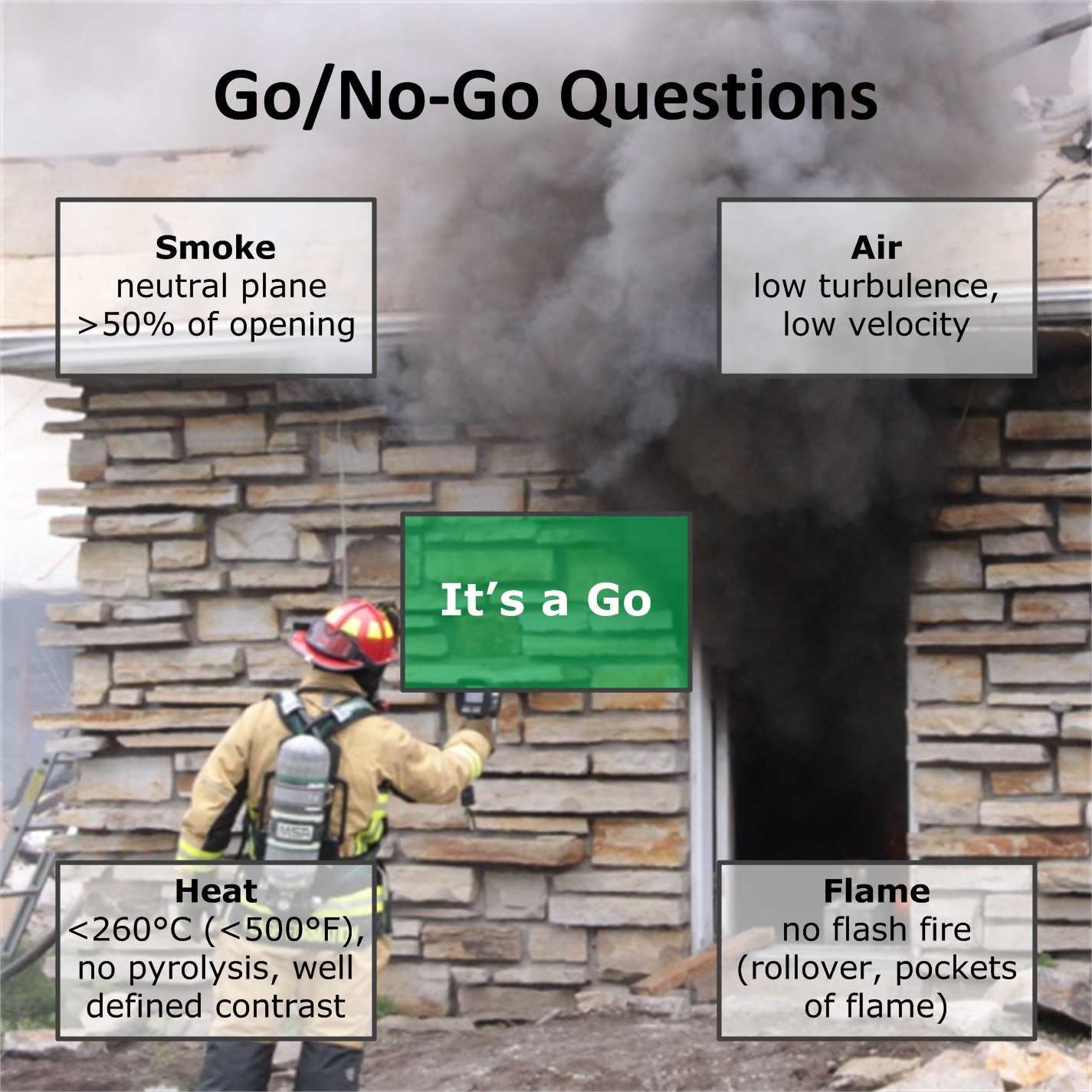

The Go/No-Go decision model evaluates four key factors:

- Smoke height (neutral plane at an opening or interface height within the structure);

- Air velocity (degree of smoke turbulence and entrainment of steam from wetting of the floor);

- Heat (thermal data such as TIC temperatures of ≥260°C (500°F) of the overall space in front of the firefighter; pyrolysis; water applied to the floor for contrast and rate of evaporation; TIC data loss due to over temperature or saturation); and,

- Flame (flash fires such as vent ignition, rollover and pockets of flame).

The model is a decision-making tool used to assist company officers and incident commanders in recognizing the potential for extreme thermal conditions prior to tactical advance into or within a structure. Keep in mind that a 'No-Go' decision based on the Go/No-Go criteria does not mean never go; it simply means we must mitigate these conditions prior to moving forward, bringing them in line with a 'Go' decision.

Figure 12 indicates the Go/No-Go requirements for a 'Go' decision.

Gaining Entry

Any one of the following observations would be indicative of a 'No-Go' condition, and must be mitigated prior to tactical advance into or within a structure:

- Smoke: Rapidly descending smoke layer;

- Air: Turbulent high velocity smoke;

- Heat: Temperatures at or above 260°C (500°F) of the overall space in front of the firefighter; pyrolysis; rapid evaporation of water applied to the floor; loss of contrast or TIC function due to saturation or over temperature; and

- Flame: Propagating flash fires.

Smoke and Air

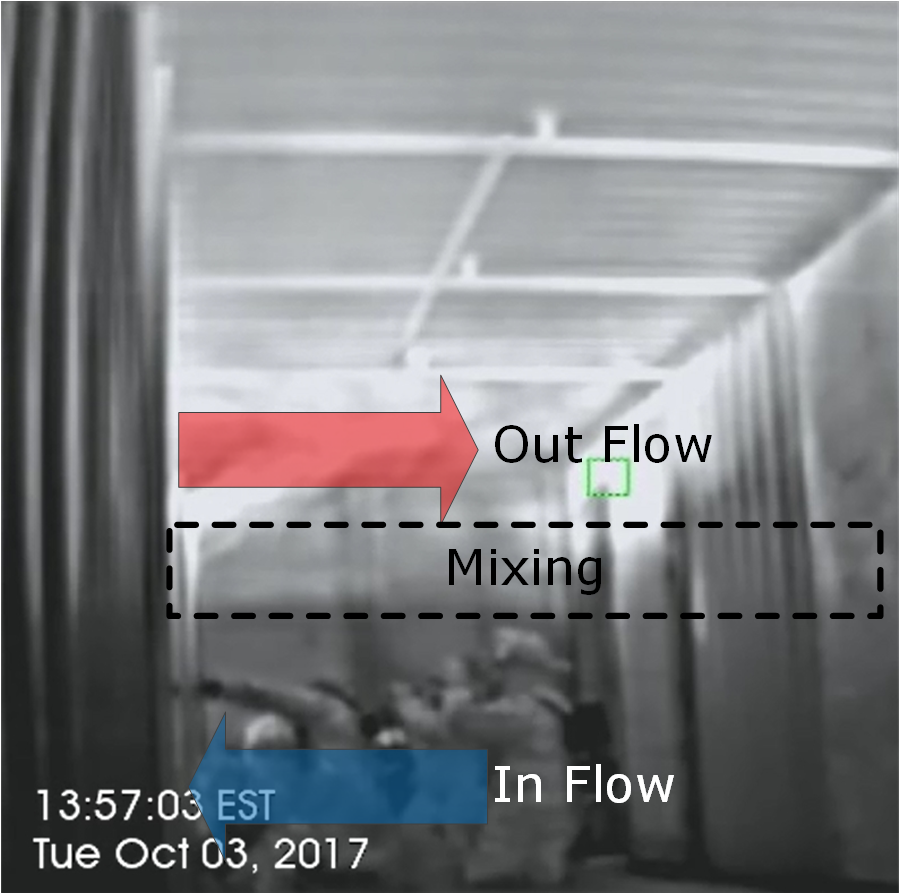

The neutral plane is a valuable indicator of a fire's growth, location and area where the fire's intake and exhaust are separated. The neutral plane may not be easily visible to the naked eye, except from the exterior. A TIC can identify the neutral plane and is often the only way to do so within a fire compartment that has heavy smoke conditions. Figure 13 shows a bi-directional flow with mixing around the neutral plane. The firefighters in this image are advancing into a bi-directional flow below, exhausting superheated smoke. The use of a TIC as part of the Go/No-Go Decision Making Model increases awareness of interior conditions to avoid operating within the heated exhaust at an opening.

A smoke layer that is rapidly collapsing/descending is indicative of fire growth, and is often accompanied by turbulent smoke due to relatively high air velocity. It is also an indicator that the fire conditions may convert an inlet opening into an exhaust. Firefighters operating in a unidirectional exhaust are exposed to unacceptable risk of serious injury or death, and many have perished under these circumstances.

As temperature increases, there will be a corresponding increase of air entrainment and risk of RFD. Given this, it is critically important to restrict air through door control or by hanging a smoke curtain to delay or limit fire growth.

Heat and Flame: Thermal Data and TIC Function

Unrestricted air results in exponential growth of the fire. PPE will not withstand the combined radiative and convective heat transfer for very long without thermal insult (PPE begins to char at 300°C (572°F), and polycarbonate SCBA lenses begins to melt at 230°C (447°F)).

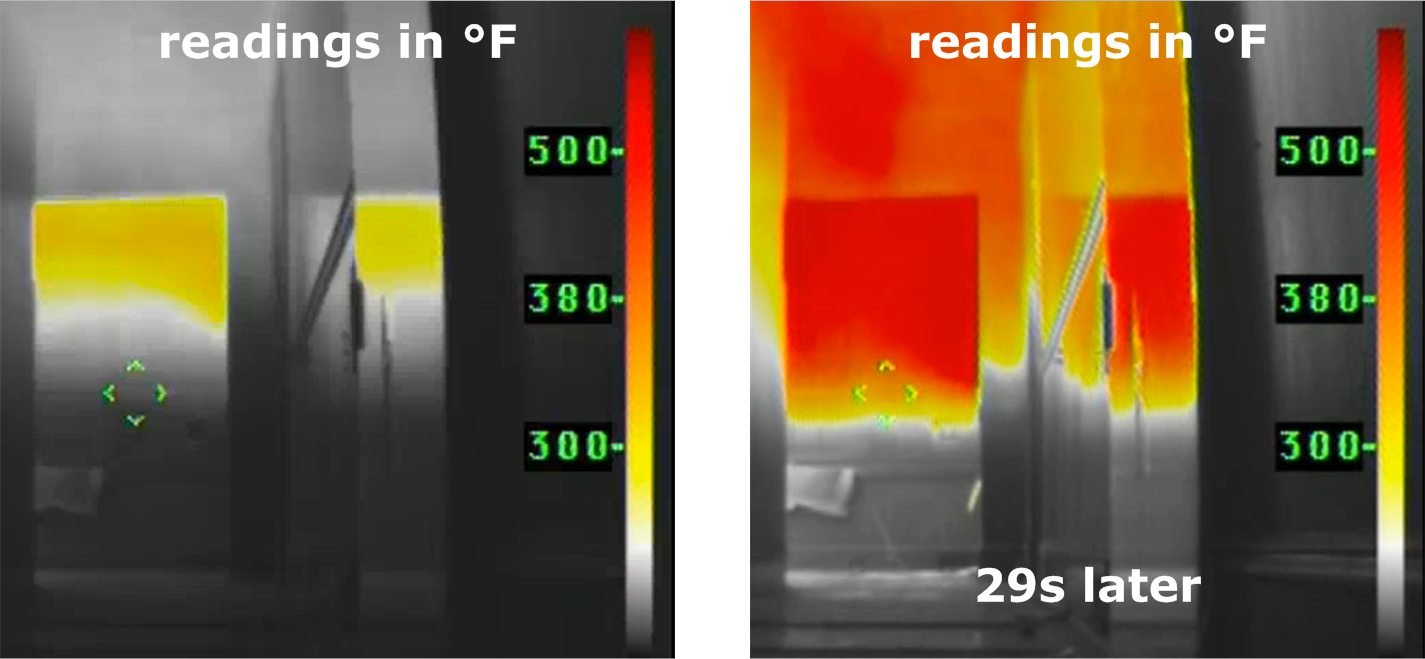

Fire-service TICs read 'apparent temperatures,' which are estimates based on a pre-set emissivity (which is 0.95 in most fire-service TICs). These apparent temperatures are to be used from a qualitative perspective and not from a specific numeric value, as an apparent temperature reading of 260°C (500°F) is often indicative of a much higher gas temperature.

Due to the limitations of PPE and TIC function, a benchmark temperature of 260°C (500°F) in the overall space in front of the firefighter is used as a benchmark for Go/No Go criteria.

Other thermal data must also be assessed to evaluate heat conditions such as pyrolysis; rapid evaporation of water applied to the floor; and loss of contrast or TIC function due to saturation or over temperature range. Pyrolysis of compartment finishes and furnishings or the rapid evaporation of water applied to the floor are both signs of significant heat energy. The loss of contrast or TIC data means the environmental temperature is moving beyond the capabilities of the TIC.

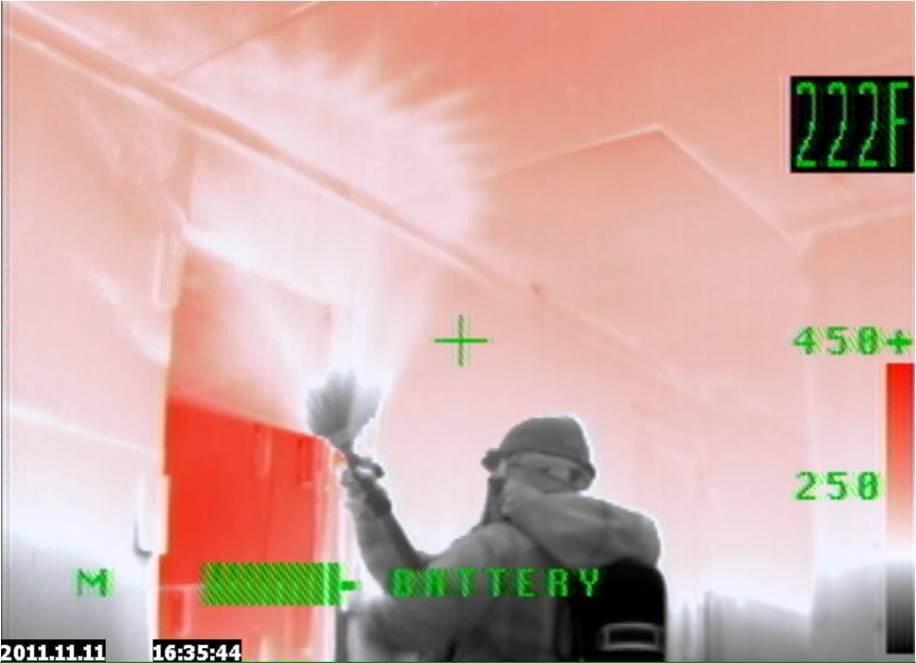

Where possible, mitigating conditions should be undertaken by water application and air restriction to cool the local environment to below 260°C (500°F). It is important to constantly test the effectiveness of your control measures. This can be achieved through visual observation and by changing the position of the focal point of the TIC to points in front of, above and behind your position. Moving the focal point allows one to more accurately observe the thermal severity of the environment and determine the conditions faced.

The Go/No-Go decision-making model is not only useful when firefighters are entering a structure. When used properly, it should also serve as a guide prior to advancing within a fire compartment. A trained crew leader should scan the environment the crew members are about to enter with a TIC, mitigate the Go/No-Go variables, clear any obstacles, and move to the next designated point within the area that was just cooled. This process should be repeated as the crew advances through a compartment or when they enter one compartment from another.

Table 1 lists the different thermal classes (shown graphically in Figure 6). A crew might move from one threshold to another threshold of a room, mitigate the environment in front of them, and then move forward. This does not guarantee that conditions will not worsen, but with the use of technology and training, it creates a more stable environment (Thermal Class II) in which PPE is meant to function for longer durations without thermal insult.

Once these variables have been addressed, firefighters should see:

- A rising smoke layer;

- Slower moving smoke;

- Thermal data below 260°C (500°F), reduced pyrolysis, and well-defined contrast; and

- No flash fires.

Table 1: Thermal classes

|

Thermal Classes |

Temperature |

Heat Flux |

Time |

|

Routine: I |

<100° |

<1 kW/m2 |

≤25 min |

|

Hazardous: II |

<160° |

<2 kW/m2 |

≤15 min |

|

Extreme: III |

<260° |

<10 kW/m2 |

≤5 min |

|

Critical: IV |

<1000° |

<100 kW/m2 |

≤1 min |

By using this model, not merely at the access point, but also as they transition through the structure, crews can maintain a thermally survivable environment.

Each compartment environment should be mitigated to fall within range of our Go/No-Go decision making model.