Water Application

Direct Application

Intent

The intent of direct application is to suppress and extinguish a fire by direct surface cooling of the burning combustibles using a straight stream or spray. Ideally, this method is used when the fire is developing or in decay. By necessity though, it is also used during interior advance and defensive operations when high flow is required, usually from a distance. Likewise, it is used during exterior control.

Nozzle Setting and Actions

- Select solid bore/straight stream or spray pattern to suit the fuel or surface area.

- Adjust the rate of movement to minimize or maximize air movement based on the fuel and ventilation conditions.

- Apply an unbroken pattern directly to burning fuels if the compartment/room is unvented opposite the attack line.

- Apply an O, T, Z or n pattern from a distance if the compartment/room has a vent opposite the attack line.

- Adjust flow rate to suit intensity and volume of fire.

Effect

- Cools the surface below the temperature at which combustion can occur.

- Can be used to stop pyrolysis.

- Care must be taken to avoid excess water damage.

- Care should be taken not to disturb embers that can become ignition sources.

- Can hold or redirect smoke flow away from an advancing crew or to a desired opening.

- Can entrain air into the fire compartment increasing HRR or disrupt the flow path.

Indirect Application

Intent

The intent of indirect application is to suppress a fire by creating large amounts of steam. This has the joint effect of gas/surface cooling, excluding oxygen from the compartment, and diluting/inerting the smoke below its flammable range. This method is generally used when the fire is fully involved or to suppress a suspected flashover or backdraft risk.

Nozzle Setting and Actions

- Use a narrow (30° to 60°) cone setting, depending on geometry of the compartment.

- Manipulate stream in an O, T, Z or n pattern to maximize steam production.

- Adjust the flow rate to suit the intensity and volume of fire.

Effect

- Enclosure is filled with steam.

- Cools burning combustibles and surfaces by absorbing energy.

- Steam as a gaseous agent dilutes and inerts the flammable mixture of fire gases and displaces oxygen.

- Lowers the interface layer, reducing visibility.

- Steam can have a debilitating effect on firefighters and any victims.

- Should be applied from outside of the compartment (e.g., hallway).

Smoke-Cooling Application

Intent

The intent of a smoke-cooling application is to reduce and control smoke flammability and radiation until effective water is applied to the source fire. Smoke-cooling techniques are used to control the fire environment while firefighters advance during fire attack or to perform search and rescue. By cooling hot fire gases below their auto-ignition temperature, firefighters can prevent further fire spread and the potential for flashover.

Effect

Smoke cooling is achieved by placing a fine water fog into the hot fire gases. Ideally, firefighters should avoid contact with hot surfaces to prevent the production of steam that may lessen visibility and impact any victims. The amount of fog required is dictated by the prevailing fire conditions.

This cooling effect will cause the smoke to contract more than the water can expand as it turns to steam. Therefore, with careful application, firefighters can maintain the interface layer at a stable level.

This effect is achieved by using combination fog nozzles and selecting the ideal cone angles, flow rates and pressures that will produce a droplet size not exceeding 0.3 mm in diameter. This size droplet will remain suspended in the air for approximately 3 to 4 seconds.

Firefighters need to adjust the duration and frequency of their water application to suit the: fire intensity and amount of hot smoke; temperature of the smoke; and size and volume of the compartment.

Smoke Cooling - Short Pulse

Intent

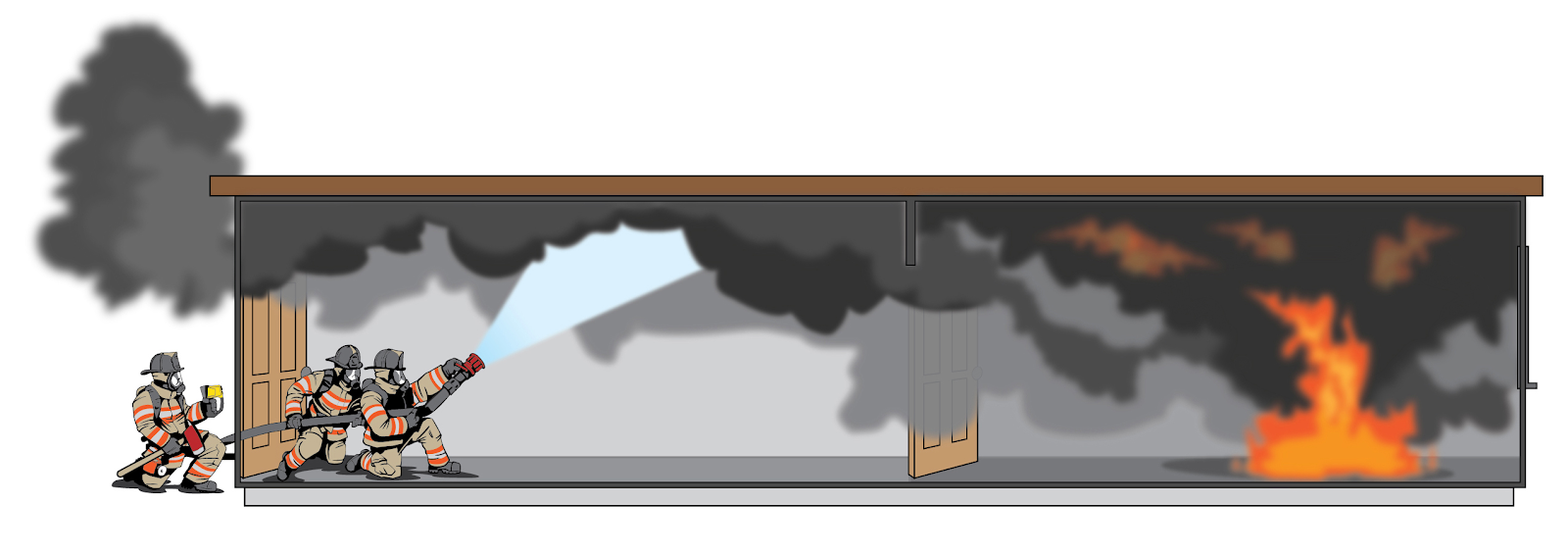

The intent of short pulses is to cool and dilute flammable gases, thereby preventing fire gases from reaching their auto-ignition temperature. The short pulse is used as soon as smoke exits above or around a hose crew, as shown in Figure 20. It is also used to dilute and cool smoke that may present a smoke ignition risk.

Nozzle Setting and Actions

- Use sufficient flow and pressure to achieve effective droplet size.

- Use a 30° to 60° cone angle.

- Fully open and then close the nozzle, all in one quick movement.

- Aim directly above and in front of the firefighters, into the upper layer.

All interior firefighting operations (including search and rescue) will require some level of smoke cooling, as all fires produce flammable fire gases. The frequency and duration of smoke cooling is dictated by the intensity of the fire and the amount of hot fire gases (smoke).

|

Don't ask if you should; decide how much! |

Smoke Cooling - Long Pulse

Intent

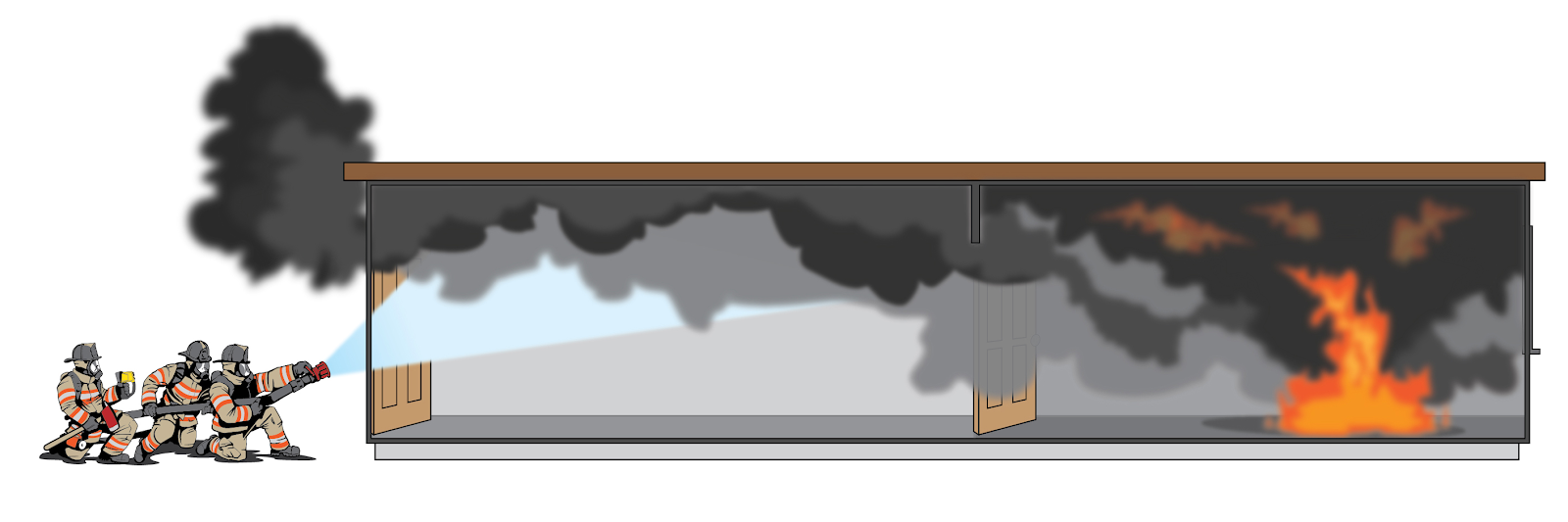

The intent of using long pulses is to cool and dilute the flammable gases thereby preventing the fire gases from reaching their auto-ignition temperature. The long pulse should always be used aggressively when there are large amounts of smoke and/or compartment size requires greater penetration, as shown in Figure 21.

Nozzle Setting and Actions

- Use sufficient flow and pressure to achieve effective droplet size.

- Use 30° to 45° cone angle (narrower than short pulse).

- Open the nozzle for approximately 1 to 2 seconds.

- Aim in front of the firefighters into the upper layer.

Long-pulse smoke cooling is critical at most fires. A hallway filled with hot smoke from a kitchen fire can be dealt with quickly by a well-aimed long pulse.

|

The frequency and duration of smoke cooling is dictated by the intensity of the fire and the amount of hot fire gases (smoke). |