2.1 Installation – General

Blown fiber glass insulation generally can be installed in all ceiling and sidewall areas as well as in other exposed areas such as over- hanging floors.

Loose fill is properly specified by R-value, not inches of thickness. The "R'' stands for resis- tance to the flow of heat and is a measure of how effective the installed insulation will be.

The higher the R-value the greater the insu- lating power. Ask your seller for the fact sheet on R-values.

It is important that the R-value being considered is the value for the total amount of insulation used. R-value per inch can be misleading because the amount and the thick- ness required may vary with products of different manufacturers.

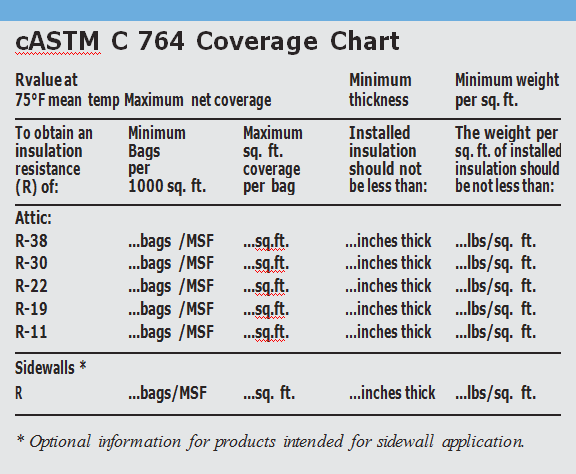

In order to achieve the specified R-value, loose fill must be installed so that at least the minimum thickness and weight per square foot are achieved. The only practical way to do that is to be sure to install at least the minimum number of bags per 1000 square feet as speci- fied on the label coverage chart. ASTM Standard Specification C 764 requires a coverage chart, a sample of which follows. On an actual label, the coverage chart will show numbers representing specifications for the particular manufacturer's product. Refer to the label specification on a bag that you use.

The number of bags per 1,000 sq. ft. is based upon net area, which is the total area minus the area covered by framing members and other obstructions, while job size is usually figured as total (or gross) area.

Because the net area will always be smaller than the gross, the number of bags per 1,000 sq. ft. of gross area may be reduced slightly, generally 3 to 8 percent, from the number on the label. Manufacturers may provide correc- tion factors or tables to make this adjustment. However, the bag label makes no allowance for the additional material that might be needed where blowing is difficult, such as under flooring or at obstructions where the insulation may pack.