Getting Better Everyday – By Gord Cooke

August 15, 2018

This April saw the fifth annual Building Science Spring Training Camp, which we at Building Knowledge Canada were pleased to host with Tex McLeod. Tex always designs a comprehensive and complementary agenda that incorporates a nice range of different learning experiences to ensure the event is fun, interactive and memorable. This year was no exception, with a formal debate (well, more fun than formal, along the lines of the popular CBC Radio The Debaters program), followed by an open mic night and a movie night (including popcorn).

A complementary session by Jeff Armstrong of Cold Climate Building in Ottawa highlighted work he has been doing on creating a panelization system for deep energy retrofits of existing homes. The premise of Jeff's work is that we are going to need a way of effectively re-skinning the millions of poorly insulated existing homes with high levels of insulation if we are to really make a dent in aggressive energy efficiency targets.

Jeff's process is helped by new technology that can precisely and quickly measure the exterior façade of a building to facilitate the off-site manufacturing of precision insulated panels to reface the building. Jeff and his team, with help from Natural Resources Canada, have demonstrated proof of concept on a simple trailer building and now will apply it to an actual row house project. Both John and Jeff reminded the audience that the off-site manufacturing of components requires a fanatical focus on methods that ensure on-site assembly results in thoroughly water- managed building enclosures. After all, the longevity and sustainability of houses starts with proper detailing of water-resistant barriers.

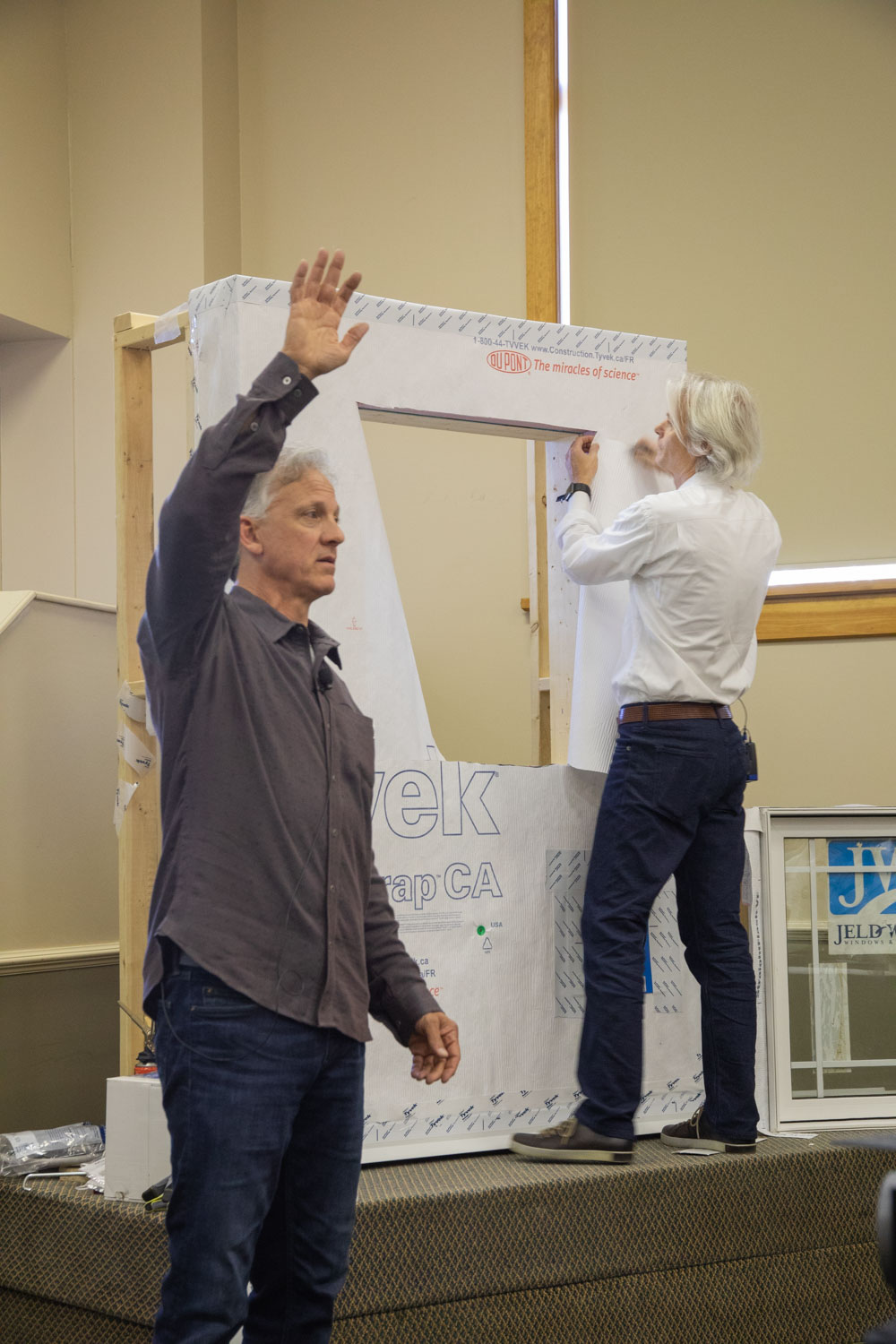

Mark LaLiberte (left) and Justin Wilson of Construction Instruction.

I was so pleased that my good friends, Mark LaLiberte and Justin Wilson of Construction Instruction from the U.S., were able to come to Advanced Building Science Spring Training Camp. In preparation for Camp, Mark and Justin had sent up plans for mock-up walls so that they could demonstrate valuable techniques for proper installation of water-managed windows and doors.

Mark and Justin are so passionate about the importance of hands-on learning for our industry that they have set up a new learning centre in Phoenix, Arizona. In this new facility, builders and their trade partners can attend a two-to three-day learning event and play around with different materials and installation techniques for weather barriers, thermal barriers and air barriers, and then actually test the performance of what they have learned. This new, unique learning experience is called Ci Live. I am certain many readers can think of more than a few of their staff or partners who would benefit from a high-level, in-depth opportunity to learn. Ci Live helps participants really understand the attention to detail required by our increasingly complex buildings (and expected by our home buyers).

NRCan's Jeremy Sager presents findings on hybrid heating as a means of reducing CO2 emissions.

The three Camp sessions mentioned above were just Day One in Huntsville. If we are to respond to the challenges facing the industry with respect to skilled labour shortages, we can't just lament that "you can't find good people anymore." Rather, let's go out and invest in systems that leap-frog past the shortages - such as more prefabrication - or invest in continual and progressive training of that most valuable of resources. As you consider your own path of continual improvement, consider how much and how often your people need learning experiences. Fortunately, there are resources available to you.

For more information on Ci Live, go to www.constructioninstruction.com.

This article originally appeared in Better Builder Issue 25 - Summer 2018