Background

As the desire to provide more thermally efficient enclosure assemblies increased so did the problems with moisture accumulation within building enclosure assemblies. Often the problems occurred due to new materials being introduced into the designs for specific purposes, without adequate understanding of all of their properties and the potential impacts on the assembly as a whole. Many enclosure failures occurred due to the lack of appreciation that products and materials have other properties than the ones that they are initially designed for.

Though these lessons were hard learned, we can now use this knowledge for our benefit. Through examining and understanding materials based on all of their properties (not just what they were initially created for), we can eliminate redundancies in enclosure design, making the systems simpler and more cost effective.

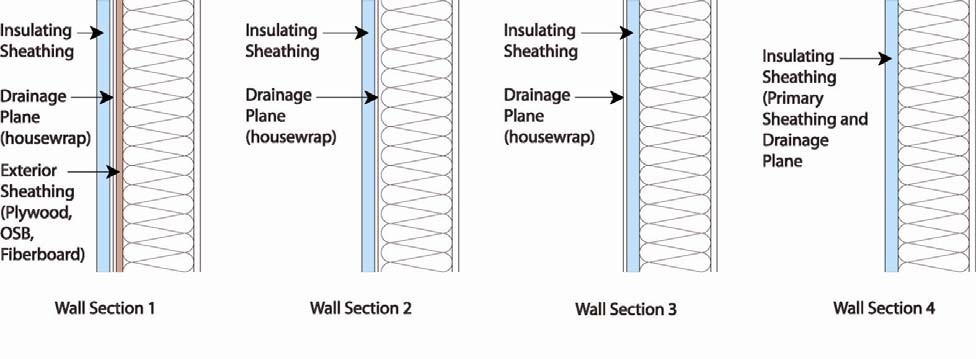

In cold climates the use of exterior rigid insulation sheathing boards has been a method of increasing thermal performance of the enclosure, as well as a means of reducing the condensation potential within exterior wall assemblies. This concept, while not new, has become more accepted in recent years and is being used in residential construction. While this method has proven to be effective, it was introduced as an addition to standard residential construction for a specific purpose. The base wall assembly generally remained unchanged, with other materials used for air sealing and water management.

The opportunity that presented itself was the integration of the exterior rigid insulation board into the enclosure assembly to act not only as insulation but also as the primary sheathing and, in certain areas, as the drainage plane and vapor control layer for the wall assembly. This system combined with advanced framing concepts can provide cost savings from the reduction of building materials used (fewer studs, the elimination of plywood or OSB sheathing, and housewraps), and the reduction of construction waste (incorporating standard construction product dimensions in the design of the building to minimize cutting).

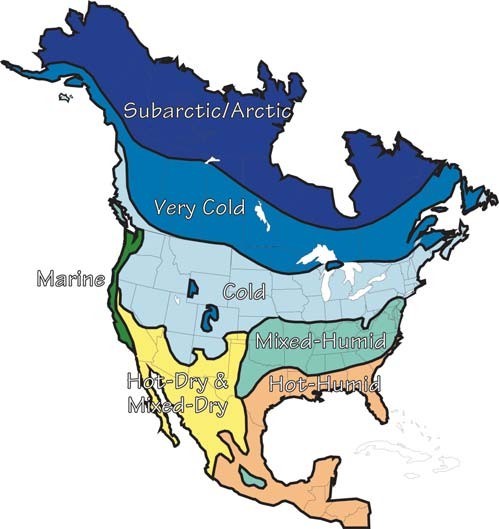

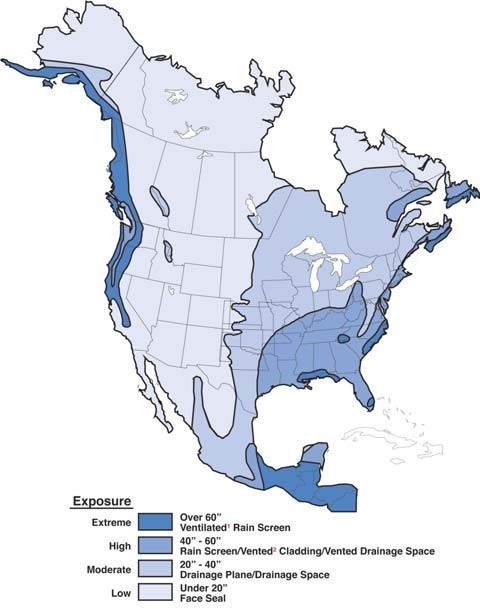

While the use of exterior insulation was initially used in cold climates, the benefits of the integrated system from increased thermal performance and reduced costs make it viable in other climates zones as well.

Still, proper understanding of the type of enclosure assemblies suitable for the overall climate zone in which the house is being constructed is critical. The choice of materials used will vary from climate zone to climate zone and the details for the water resistant barrier become more critical in areas of increased rainfall.

This guide examines the application of insulating sheathing to exterior wall assemblies, from the technical conceptual design and benefits to the installation and interaction with other building systems.