General Installation

Insulating sheathing should be installed based on manufacturer's recommendations for fastener type and amount. It is recommended to layout the insulating sheathing such that vertical joints do not occur at the corners of window and door openings or over window heads if possible.

In Wall Section 1 and Wall Section 2 the primary drainage plane occurs behind the insulating sheathing. All water management details (flashing and window installation details) should be tied back to the plane of the housewrap. In these configurations, while the insulating sheathing is not officially considered to be part of the drainage system of the wall, it will provide some protection for the housewrap in preventing much of the exterior rain water that penetrates past the cladding from penetrating through to the actual drainage plane.

For Wall Section 3, the primary drainage plane to the exterior of the insulating sheathing and more exposed to the elements. In this configuration the water management and window installation details are integrated into the housewrap at the exterior face of the insulating sheathing. Water management details would be the same as normal details of recommended good practice for wood sheathed house design.

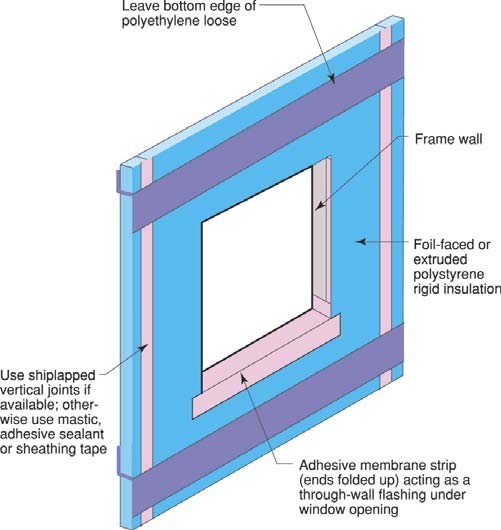

Wall Section 4 requires some special detailing. All the joints between the insulation boards must be designed in such a way as to prevent water from penetrating past the exterior face of the insulation. Sealing or taping the vertical joints should be done and if possible, products that use shingle lapped or tongue and groove joints should be used. A polyethylene flashing is recommended to be installed at the horizontal joints in the system.

In order for the insulation sheathing to be used as a water resistive barrier, the vertical plane of the exterior face of the sheathing must be as continuous as possible. This is to prevent locations within the wall assembly where drainage could be blocked or where water might be held.

For added protecting, window head flashing and roof step flashings can be easily regletted into the face of the foam sheathing providing for better protection against flashing failure and reverse flashing problems. The reglette should only penetrate into the face of the sheathing and not all the way through the sheathing.