Basements and Crawlspaces

Basements can account for one quarter of energy use in a typical house. Therefore insulating foundation walls is a critical measure for a DER project. In addition, damp basements - due to bulk water entry, moisture transfer through the walls or slab, or condensation - contribute to indoor air quality problems and durability issues. As with all of the retrofit assemblies, basement assemblies address all four of the enclosure functions. However, since the majority of a basement is below grade, the primary purpose of the air control function in the basement is to prevent the entry of soil gases.

This guide describes assemblies for insulating basements but does not provide recommendations for retrofitting insulation to the separation between the basement (or crawlspace) and the living space. This is because research by BSC and experience by others has found that even apparently well-implemented basement ceiling retrofits do not provide effective air separation between the basement and the living space. At the same time, excluding the basement or crawlspace from the thermal enclosure tends to increase air quality problems in these spaces. Therefore, for reasons of thermal performance and indoor air quality, this guide recommends that basements and crawlspaces be included in the thermal enclosure.

Foundation Walls

Most existing houses have concrete foundation walls (cast concrete or concrete block) or walls constructed of irregular discrete pieces - fieldstone, brick or rubble. For the retrofit foundation assemblies, the primary distinctions between these is the character of the surface of the wall - either a flat surface or an irregular surface - and the water permeability of the wall, which is quite high for the walls built of irregular discrete pieces. The two retrofit assemblies that use rigid insulation (XPS) - either to the interior (Foundation Wall 1) or to the exterior (Foundation Wall 3) - are only appropriate for a flat surface whereas the retrofit assembly for that uses an interior application of closed-cell spray foam insulation applied directly over the wall (Foundation Wall 2) can be used for both types of foundation walls.

Even though foundation wall materials are water tolerant, as part of the water control function for basements, measures should be taken to protect the walls from bulk water. If the grade around the perimeter does not slope away from the house, make grading adjustments so that it slopes away at 5% grade for at least the first 3 feet and if possible, 10 feet. If gutters are installed, the system must direct water away from the perimeter of the house and the gutter system must be regularly maintained to prevent overflowing, leaks, or breaks in the system as these can concentrate water onto the building. Another protective measure is to provide a trench of gravel around the perimeter that extends out at least as far as the roof drip edge. This helps disperse bulk water that comes from the roof so that the top of the foundation wall is not continually splashed. It is especially important to keep bulk water away from the exposed part of stone or brick foundation walls since this reduces the risk of freeze thaw cycles.

Before proceeding with the foundation wall retrofit, an assessment should be made of the condition of the sill. If there is no capillary break under the sill and/or if the sill is within 12" of the ground, it is possible that it has suffered water damage. If so, the damaged pieces should be replaced and, at the same time, a capillary break installed under the new pieces. If these conditions exist but there is no indication of damage, then it is likely that the sill has been able to dry. However, the retrofit foundation wall assembly limits drying to the interior, so special treatment may be required at the base of the exterior wall. This is further discussed in Transitions section.

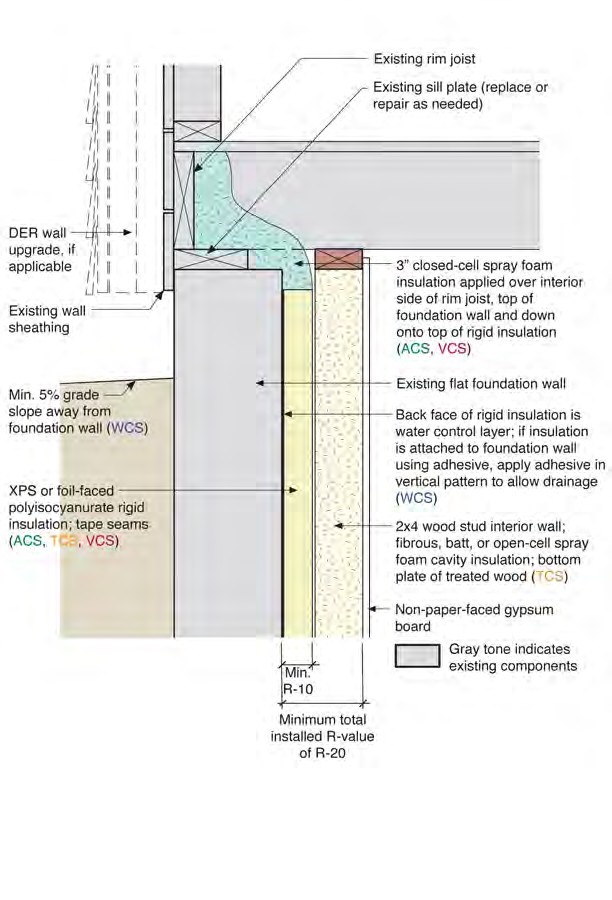

Foundation Wall 1: Rigid Board Insulation with Insulated Stud Wall to Interior of Flat Foundation Wall

- This assembly is not applicable for basements subject to flooding.

- Any cracks in the foundation wall should be patched.

- Do not use a cavity insulation that is vapor impermeable.

- If metal rather than wood studs are used for the interior wall, leave at least a 1" gap between the metal studs and the rigid insulation to avoid degrading the overall R- value due to conductivity of the metal studs.

- For brick walls, take measures to protect the exposed part of the foundation wall from bulk water to reduce the risk of freeze-thaw cycles and to reduce capillarity.

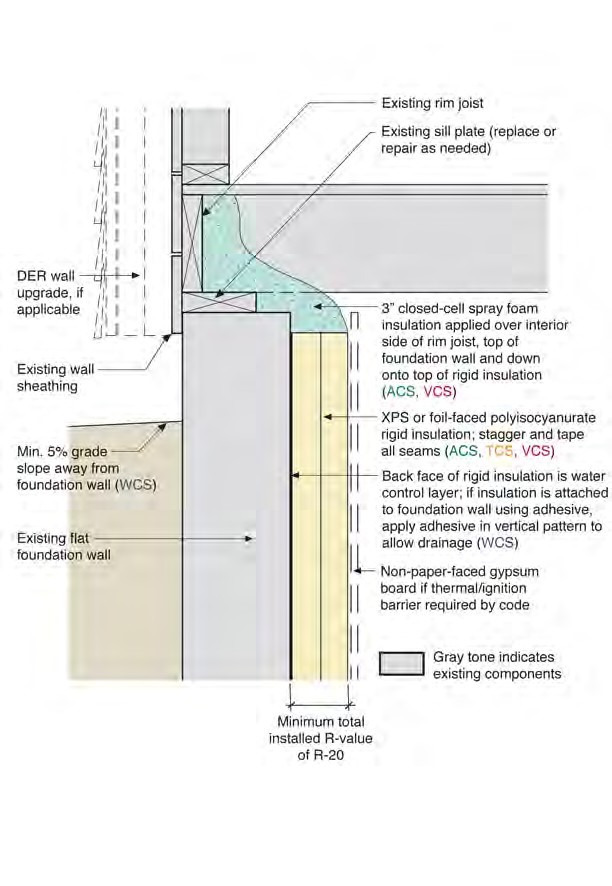

Foundation Wall 1 Alternate: Rigid Board Insulation to Interior of Flat Foundation Wall

- For brick walls, take measures to protect the exposed part of the foundation wall from bulk water to reduce the risk of freeze-thaw cycles and to reduce capillarity.

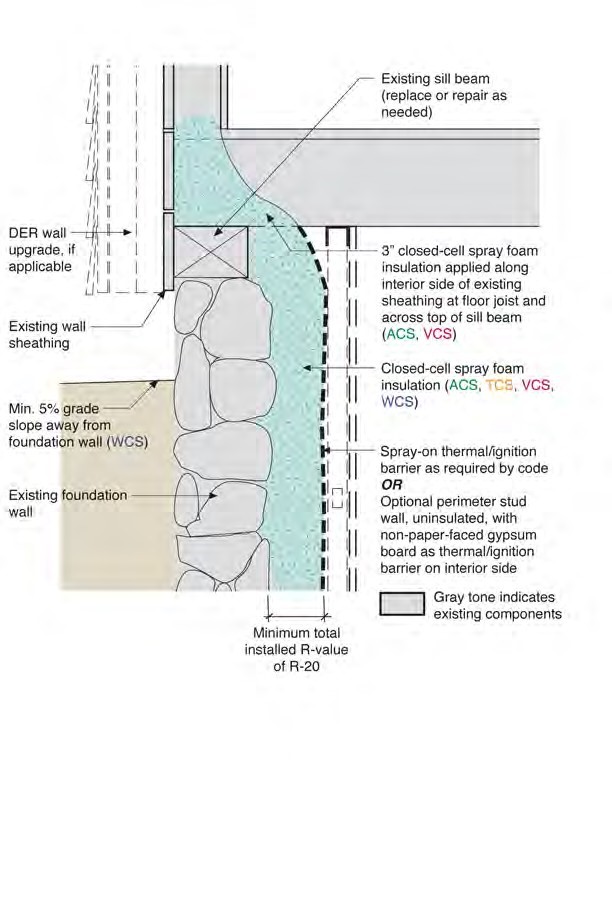

Foundation Wall 2: Closed-Cell Spray Foam to Interior of Foundation Wall

- This assembly is appropriate for stone or rubble foundation walls as well as for flat foundation walls.

- If the house has balloon framing, the spray foam insulation at the top of the foundation wall needs to extend into the base of the wall cavity above and seal to the back side of the existing wall sheathing, as shown.

- If the optional metal interior stud wall is provided, the stud wall should not be insulated unless the metal studs are placed at least 1" to the interior side of the foundation wall insulation.

- For stone or brick walls, take measures to protect the exposed part of the foundation wall from bulk water to reduce the risk of freeze-thaw cycles and to reduce capillarity.

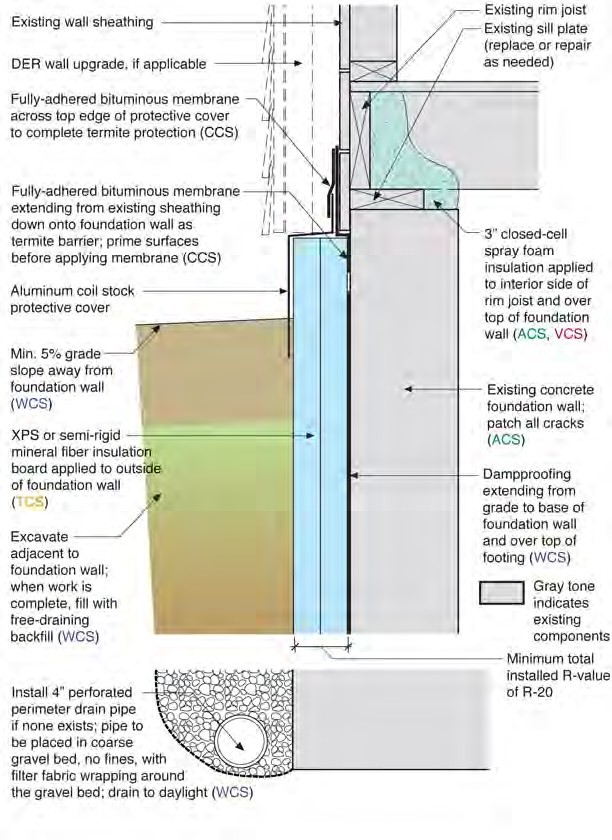

Foundation Wall 3: Rigid Insulation to Exterior of Flat Foundation Wall

- This assembly should only be used on a flat foundation wall.

- While appropriate for new construction, this method is rarely applied to a retrofit because of the cost and logistical difficulties.

- An alternative type of protective cover may be used, but flashing across the top of the exterior insulation must be provided and it must be sealed at the top with membrane as shown.

- For a concrete block or brick foundation wall, an air control layer, such as a parge coat, should be applied on the interior with a continuous transition to the spray foam at the top of the wall for air control.

Slabs

Today, basement slabs are constructed over gravel, insulation, and a vapor barrier. This treatment minimizes moisture transfer and heat loss through the concrete slab. However, homes built before the 1990's typically did not use these techniques so most retrofits cannot assume this type of treatment exists under the slab. Therefore, the retrofit of the basement slab needs to address both moisture transfer and heat loss through the slab. In addition, it may need to support the water control strategy of the basement walls.

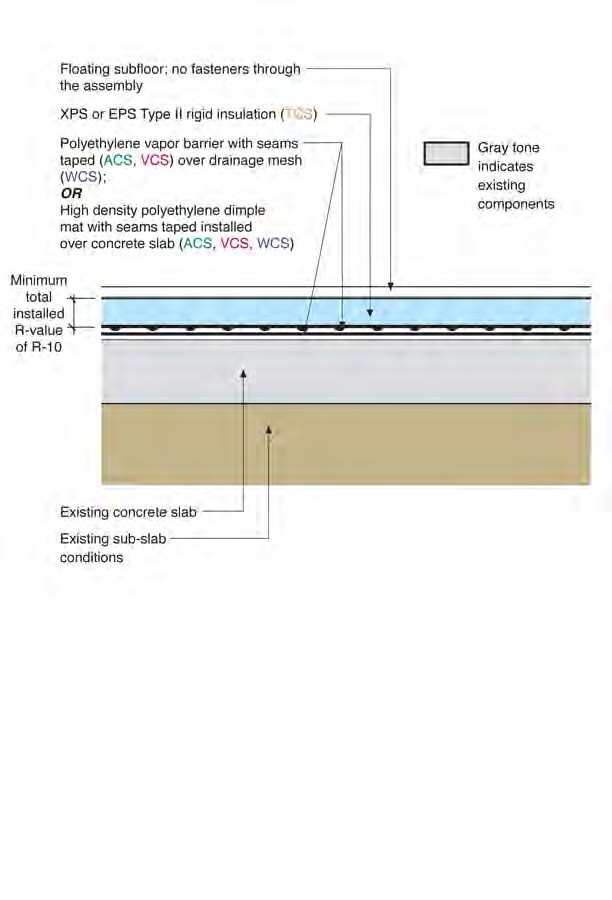

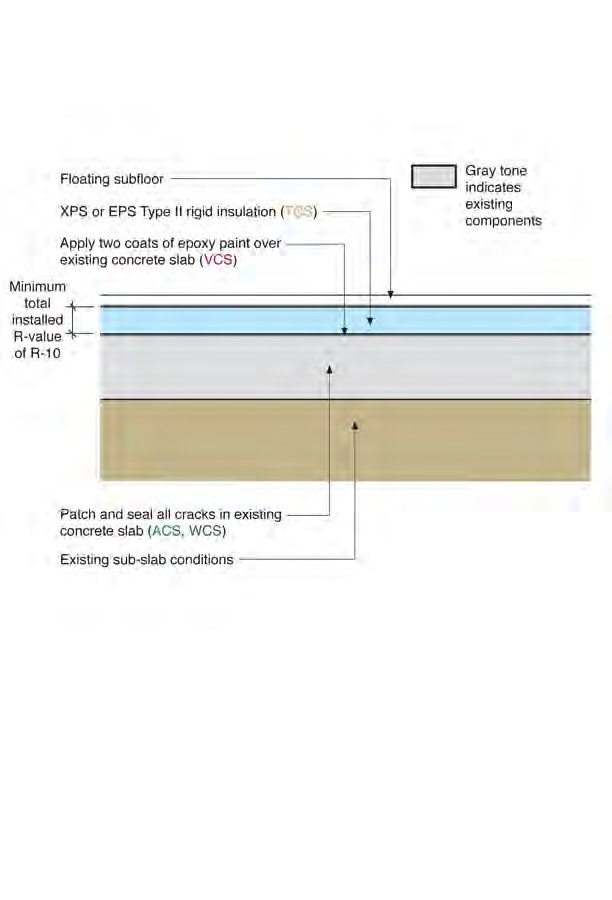

If the existing basement slab is uninsulated, there are two options for adding insulation: one is to remove the existing slab, excavate below and construct an insulated slab along with other appropriate moisture transfer protection below; the other is to provide insulation and water control on top of the existing slab. Replacing the slab is generally not a feasible approach for a retrofit. Therefore, the two retrofit assemblies supported in this guide are insulated above the existing slab by applying 2" of XPS insulation over the existing slab and covering it with a subfloor material. Basement Slab 1 includes a water drainage space underneath the insulation to allow water to be drained over the existing slab to a sump or other drainage system. This drainage space is completely isolated from the interior by vapor and air impermeable materials. Basement Slab 2 does not include the water management on top of the slab and thus requires installation of a perimeter drain system tied into a sump or other drainage system.

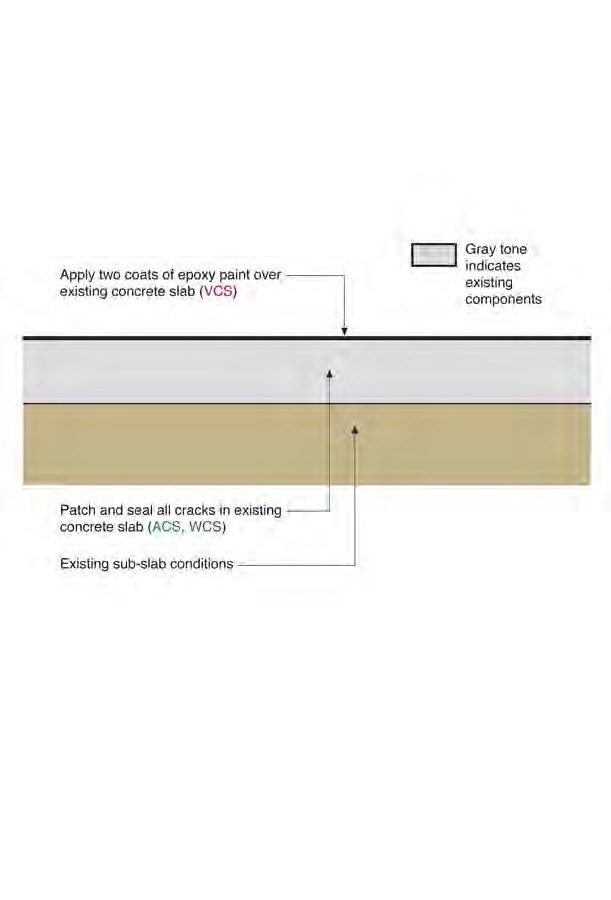

In some cases, it is not possible to add insulation over the existing basement slab due to insufficient head height in the basement. There are risks associated with a slab that is exposed to the interior and in contact with cooler damp soil. These risks are managed by 1) treatment of the slab, 2) control of conditions in the basement, and 3) separating sensitive materials from the slab. If the post-retrofit basement slab is uninsulated, at a minimum, the slab should be patched and sealed to the foundation wall for soil gas control and an epoxy paint should be applied to the surface for moisture transfer control. The homeowner should consider the use of a dehumidifier in the basement during the summer. If the basement slab is already insulated, the application of epoxy paint is recommended but not required.

Slab 1: Insulation Over Existing Slab with Drainage Layer Between Insulation and Existing Slab

- The above-slab drainage layer (drainage mesh or dimple mat) must be connected to an interior sump pit. The interior sump pit must have an air tight and gasketed cover.

- Through-assembly fasteners should not be used because these would puncture the air and vapor control layers potentially admitting soil gas that is collected in the air space below (drainage mesh or dimple mat).

Slab 2: Insulation Directly Over Existing Slab

- Use of this slab assembly requires a sub-slab drainage system.

Uninsulated (or Existing Insulated) Slab Assembly

- If the existing slab has continuous insulation below the slab, then the epoxy paint is recommended, but not required.

- Water sensitive materials should not be placed in direct contact with the slab.

Crawlspace Floor

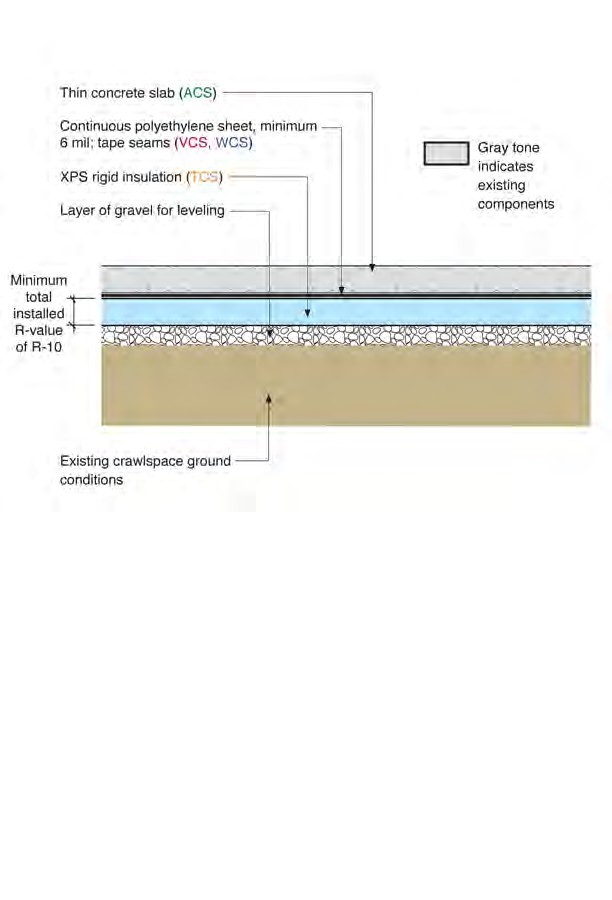

Because it is important to include the crawlspace in the thermal enclosure, measures are needed to treat the floor of this space. In many cases, the crawlspace may be treated as a short basement and retrofit foundation wall and retrofit slab assemblies as described above may be applied. In other situations, the existing conditions require other solutions. Below are two assemblies appropriate for retrofit of crawlspaces having exposed dirt or gravel floors.

Crawlspace Floor 1: Insulation and Thin Slab Over Dirt/Gravel

- This crawlspace floor assembly provides a surface suitable for light storage.

- If there is a history of flooding or water leakage in the crawlspace and there is no functioning perimeter drainage system, a drainage system (e.g. an interior perimeter drain or gravel layer connected to an interior sump pit) must be installed under this assembly. An interior sump pit must have an airtight and gasketed cover.

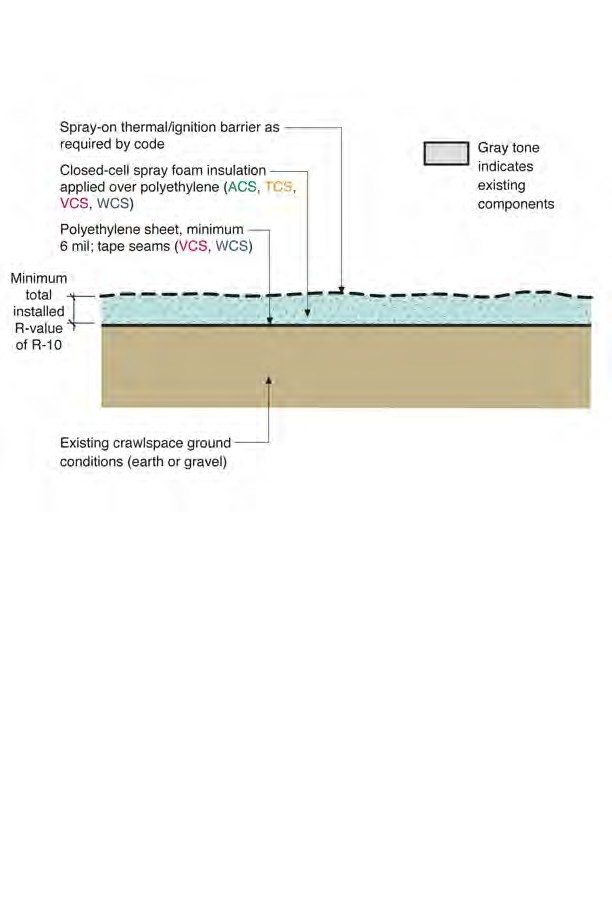

Crawlspace Floor 2: Closed-Cell Spray Foam Over Dirt/Gravel

- This crawlspace floor assembly is to be used with treatment of crawlspace walls as described for Foundation Wall 2.

- This assembly should not be used under a (future) concrete slab.

- This assembly is not appropriate in a crawlspace that needs to be frequently accessed.

- If there is a history of flooding or water leakage in the crawlspace and there is no functioning perimeter drainage system, a drainage system (e.g. an interior perimeter drain or gravel layer connected to an interior sump pit) must be installed under this assembly. An interior sump pit must have an airtight and gasketed cover.