Types of Building Insulation

Faced Insulation

Batts and rolls are available with facings already attached. The facing material is usually a vapor retarder. Vapor retarding facings usually consist of asphalt-coated kraft paper, aluminum foil or plastic film. A vapor retarder's purpose is to resist the movement of moisture vapor to colder surfaces where it could condense to water.

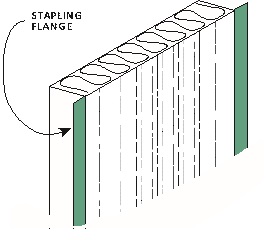

Most facings extend over the sides of the insulation to provide flanges that can be stapled to wood framing to hold the insulation in place when recommended by the manufacturer. Some faced products may be pressure fit between framing without stapling. Pressure fit is acceptable for standard wall heights but for walls that are above 8 ft. you may want to consider stapling to keep in place until drywall is installed.

Carefully read the manufacturer's directions printed on the insulation packaging to be sure the material is correctly installed.

Unfaced Insulation

Unfaced wall insulation is usually made wider to permit installation by pressure fitting between either wood or metal framing. No fastening is required if the insulation material is enclosed on all four sides and fills the cavity, as in a typical wall cavity installation.

Insulation Sizes

Insulation is packaged as batts or rolls and is available in a variety of sizes. Not all sizes are produced by every manufacturer. The following table represents common material sizes.