Securement

When cavities are more than 8 ft. high, or you are using standard or lighter density batts, or insulation does not completely fill the cavity, mechanical securements are necessary.

Tape Method

Place the facing flat against the face of the stud. Tape the tab to the stud using 4 inch to 6 inch pieces of duct tape, contacting the facing and wrapping around on the stud. Install the adjacent piece of insulation in a similar manner. Allow the tab of this piece to lay on top of the adjacent piece and tape flat. When gypsum board is installed, the tabs are continuously impaled between the gypsum board and stud face. When tabs are laid flat, they will not interfere with gypsum board. (See Figure 9.)

Mechanical Fasteners

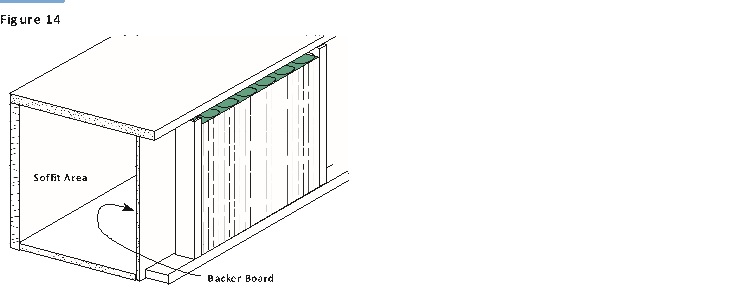

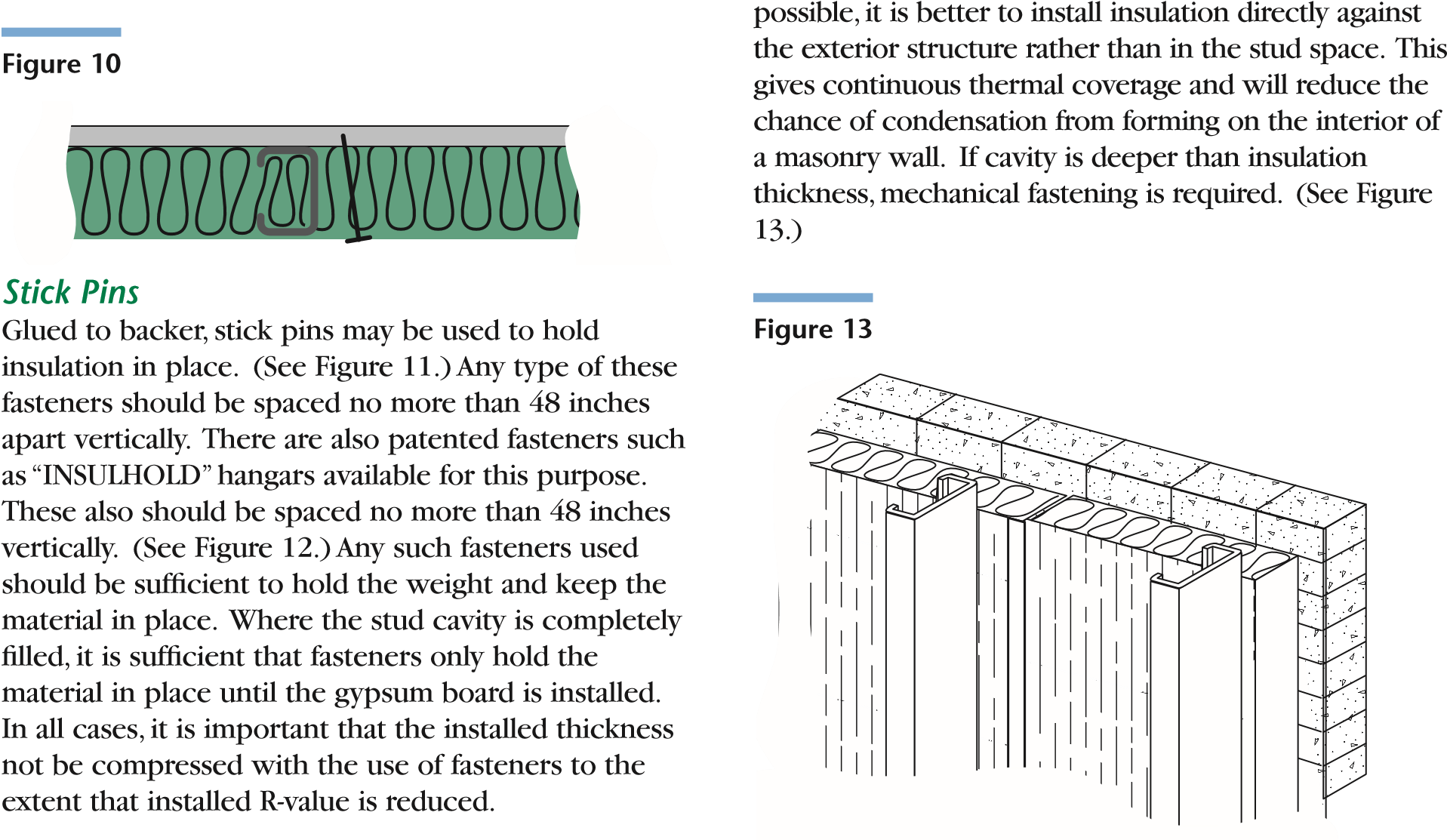

Various forms of mechanical fasteners may be used to secure insulation in a stud cavity. If backing material is nailable, common nails can be used through body of insulation into backer material. (See Figure 10.) Do not nail so as to compress insulation more.

FIGURE 11

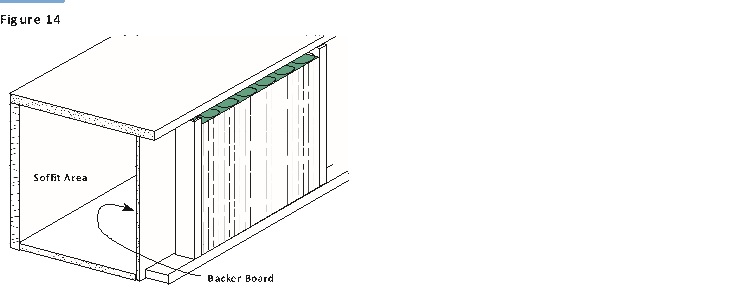

Various Pin Types Pin layouts where surface will not

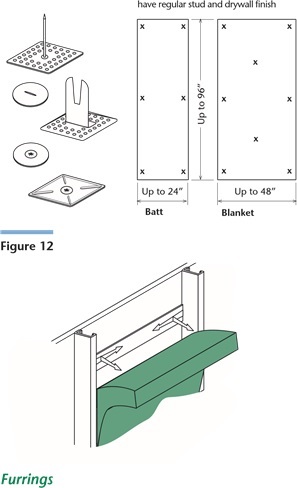

Furrings

Studs are often furred out from wall structure leaving a cavity between back of wall and stud. Whenever Furrings above store front,entryways and at back of soffits present special problems. In these cases, adequate mounting for insulation must be provided. A stud system with an exterior sheathing to seal off the space and insulation between the studs is best. A "hanging wall"of unsupported insulation to close such areas should not be depended upon to provide either thermal or air infiltration control. (See Figure 14.)