Floors

Insulation is installed between floor joists, and secured as follows:

Wire Fasteners

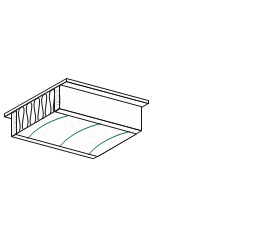

The easiest and most effective method of holding insulation in place is to use straight,rigid wire fasteners,(preferably galvanized,) with pointed ends. The fasteners are made for joist spacing of 12,16,18, 20 and 24 inches and may be used against wood, metal,or concrete. The fasteners,which are slightly longer than the joist spacing,are placed by hand between the joists and bowed upwards into the insulation,causing the insulation to be in contact with the sub flooring. Install the fasteners so they hold the insulation in contact with the sub floor but avoid unnecessary compression.Spacing of fasteners is as required to prevent sagging of the insulation,normally 12 to 24 inches apart and not more than 6 inches from ends of the insulation. (See Figure 18.)

Figure 18

Mesh or Screen

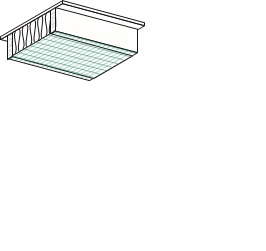

Galvanize d wire, nylon mesh or galvanized screen (chicken wire is also suitable) will hold the insulation in place. After the insulation has been pushed into place the mesh or screen is stapled or nailed to the joist faces . (See Figure 19.)

Figure 19

Wire Lacing

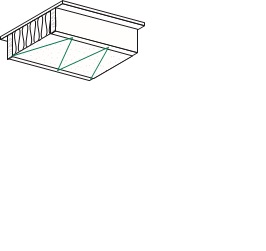

Galvanized, malleable wire may be laced around nails protruding from the faces of the joists or the wire may be stapled to the joists. Wire and nail spacing are as required to prevent sagging of the insulation. (See Figure 20.)

Figure 20

Note: For homes where the underside of the floor is exposed and readily accessible,such as homes on pilings or certain garage areas,the insulation should be covered with a suitable exterior material to protect it from high winds and physical abuse. Header and band joists should also be insulated and air-sealed.

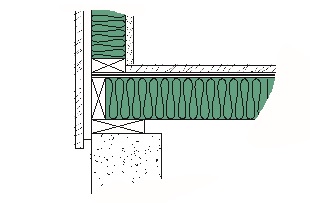

When insulating floors where the insulation is less than the thickness of the joists and the method of installation does not hold the insulation up against the subflooring, the headers or band joists at outside walls must be insulated. This is because there will be an air space between the top of the insulation and the subfloor which will allow heat to bypass the installation. Therefore, it is recommended that the insulation be pushed up to the subfloor. If insulating over an unheated area, the vapor retarder should be in substantial contact with the subfloor. Where the header is parallel with the floor joists it may be necessary to adhere insulation to the header or fill the joist area with insulation. (See Figure 21.

Figure 21

Open Web Trusses - Wood

Effectively insulating open web, wood trusses with batts can be difficult. When using batts, they must be carefully cut and fit between the openings in the webs and supported by rods or wire. Consider insulating this type of assembly with loose fill fiber glass blown above a mesh-type membrane attached to the lower chords of the trusses. When a vapor retarder is required, the supporting material should have a rating of less than 1 perm.

Open Web Trusses - Steel

Open web steel trusses should be insulated with batt or blanket insulation. The insulation should be placed snugly within the floor cavity so that the edge of the insulation expands into webs of the steel truss and contacts the insulation in the adjoining floor cavity. The insulation should be installed at the bottom chord and supported using wire fasteners, wire mesh/screen or wire lacing.

Consider insulating this type of assembly with loose fill fiber glass blown above a mesh-type membrane attached to the lower chords of the trusses. If a vapor retarder is required,the supporting material should have a rating of less than 1 perm.

Pre-Engineered Trusses (I-Shaped)

For spacings greater than 24 inches, consider wide roll insulation format or contact a metal building laminator. Pre-engineered trusses should be insulated by installing the insulation at the bottom chord of the truss and supported using wire fasteners, wire mesh/screen, wire lacing or meshtype membrane. If a vapor retarder is required, the supporting material should have a rating of less than 1 perm.