Basement Walls

Unconditioned Basements

Most manufacturers produce a special product for insulating walls of unconditioned basements. They come in rolls or batts that are attached to the top of the basement wall and hang down to either partially cover or fully cover the basement walls, depending on the local building code. The material is typically supplied with a fire rated facing which protects the insulation material.

Conditioned Basement Walls

Prior to insulating basement walls with any of the following methods,insulate the band joists separately.

Furring Strips on Masonry or Concrete

Masonry wall insulation ranges from R-6 to R-8, (1-1/2 to 2-1/2 inches thick) and is unfaced. It is available for use with furring strips 16 and 24 inches on center. After the furring strips are mounted on the wall, the insulation is placed between the furring strips and is held in place by pressure at its sides. Be sure the insulation fits tightly at top and bottom.

If the vertical furring strips are aligned with the floor joists above and do not abut an upper horizontal furring strip, the insulation should extend into the space between the joists to insulate the sill and the header. Where the floor joists run parallel with the wall (no joists meet the header), secure the insulation to the sill and insulate the header separately. If a vapor retarder is desired, polyethylene film or foil-backed gypsum board can be installed.

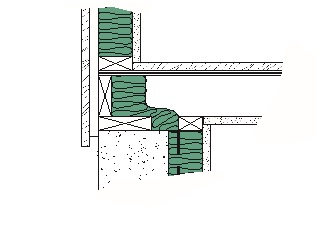

Masonry or Concrete with Framing

When insulation of higher R-values (R-11, R-13, R-15, R-19 or R-21) is to be installed on a masonry wall, a separate frame wall may be built of 2 x 4 or 2 x 6 studs.The top plate is nailed to the underside of the joists or to blocking between joists.

Attachment of the insulation to the framing is the same as for sidewall insulation. Here, too, faced or unfaced insulation may be used, with the vapor retarder applied the same way. Standard vapor retarder facings must be covered with the interior finish material (paneling, 1/2 inch gypsum board, or the equivalent). Only special low flame-spread vapor retarder facing can be left exposed. Consult individual manufacturers' instructions. (See Figure 22.)

Figure 22

All Weather Wood Foundation

Insulation is installed in the same way as in framed walls elsewhere in the building.

Sill Sealer Insulation

Sill sealer is normally available in 50- to 100-foot rolls, up to 6 inches wide and 1 inch thick. Placed between the top of masonry foundations and the sill plate, it resists heat loss by reducing air leaks, keeps out insects, and reduces the need for caulking. After laying the sill sealer on the foundation wall, the sill plate is fastened, compressing the sill sealer between the foundation wall and the sill plate.