Thermal Insulation

The design of a thermally resistant assembly requires the use of materials and components with low thermal conductivities that are combined to create a continuous thermal insulation layer. Continuity of the thermal insulation is crucial to achieving maximized effective assembly thermal resistance. Only materials with high thermal resistances or low thermal conductivities (good thermal performance) should be used as part of the thermal insulation layer. All materials and components of the enclosure assembly must be accounted for in the calculation of its effective R-value.

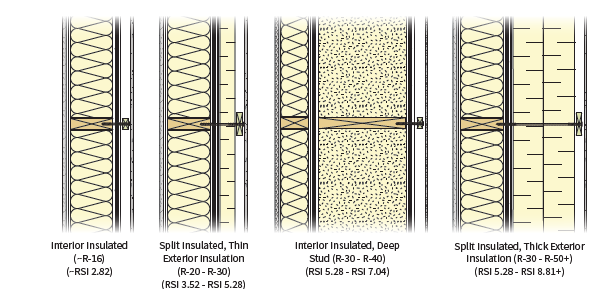

As shown on the climate zone map of Canada on page 7, the range of effective R-values that can be used varies widely. Increasing the thickness of the insulation and focusing on continuity, especially at details and transitions, is the best way to increase the effective R-value of the assembly. Current standard assemblies have to be adjusted to accommodate greater thickness of the insulation as shown below, though the overall construction approach can often remain unchanged.

Example thermal insulation improvements to reach near net zero: conventional 2x6 and 2x4 wood-frame wall assemblies can often remain as the structural basis, but additional insulation will have to be accommodated within the assembly or at the exterior face.