Exterior Insulated Walls

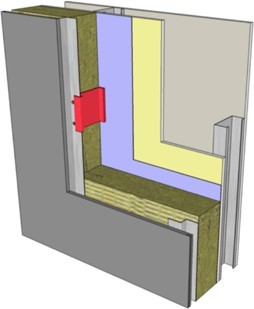

Instead of insulating walls within the stud cavity, exterior insulation can be used, and this approach to insulating wall assemblies can also be effective for concrete or CMU (concrete masonry unit) walls. In these walls, insulation is installed on the exterior of the wall sheathing or, less commonly in commercial buildings, is installed as the wall sheathing itself. This section primarily addresses the case where it is installed exterior of the sheathing.

Exterior insulation is often considered an effective way of achieving highly insulated wall assemblies, and can substantially reduce thermal bridging. In addition to these thermal benefits, exterior insulation can also provide a robust assembly with respect to vapor diffusion and condensation.

The use of exterior insulation changes the temperature profile through the wall assembly and consequently the back-up wall, be it sheathed steel stud, concrete or CMU, is maintained relatively close to interior conditions. Additionally, since typically a sheathing membrane is applied to the back-up wall behind the insulation in these assemblies, moisture-sensitive materials are generally all located on the interior side of the insulation and sheathing membrane where they remain both warm and dry, resulting in a very durable wall assembly in all climates.

In cold climates, a vapor impermeable sheathing membrane can be used to control vapor diffusion through these wall assemblies. As moisture in the air diffuses from the interior towards the exterior, the sheathing membrane restricts this diffusion while still on the warm side of the insulation and consequently prevents condensation within the exterior insulation. This is illustrated in the graphic below.

of an exterior insulated wall

with vapor barrier membrane

on the exterior wall sheathing

located in a cold climate.

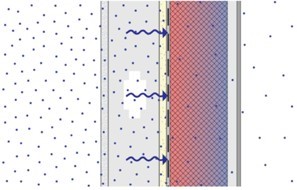

Interestingly, an advantage of fully exterior insulated wall assemblies is that in many cases vapor diffusion control is actually not required. For example, in a cold climate, if a vapor permeable sheathing membrane is used instead of a vapor impermeable membrane, vapor from the interior will be able to diffuse from the interior to the exterior relatively unrestricted. This vapor will likely condense as it moves outward on a surface such as the back of the cladding; however, materials installed on the outside of the sheathing membrane should be durable to wetting, and consequently the amount of moisture deposited from vapor diffusion condensation is unlikely to be detrimental. To accommodate this potential wetting, exterior insulated assemblies without a vapor control layer (i.e. "vapor open") should include venting of the cladding to allow drying. Where more extreme humidity levels exist, such as pools, this vapor open approach may not be appropriate, and a vapor barrier would likely be required.

Similarly, in a warm climate, as moisture diffuses inward through the assembly it will reach a cold surface at the sheathing membrane. This membrane is intended to prevent liquid water intrusion from the exterior building, and consequently wetting of this surface by condensation is within the expected performance characteristics of the material and is unlikely to cause damage. Similar to a cold climate, the area between the sheathing membrane and cladding should be designed to allow for drainage and drying of any moisture which accumulates.

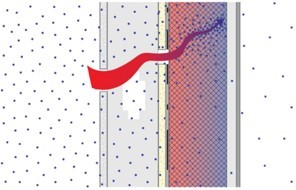

An important aspect of exterior insulated walls is that their design makes them highly durable with respect to condensation due to air leakage. While air leakage in a stud cavity insulated wall can often lead to damage, this risk is substantially reduced in an exterior insulated assembly. For example, in a cold climate, if warm, humid interior air were to leak through an exterior insulated assembly, it is unlikely to condense on any moisture- sensitive surfaces inboard of the insulation. Instead, it will condense on exterior materials such as the cladding, and these materials are durable to wetting. One notable exception to this is when the exterior temperature is below freezing. In this case, leakage of interior air to the exterior can create substantial ice build-up on cold surfaces such as the cladding, and this ice may damage the assembly.

The following graphics illustrate exterior insulated walls where no vapor retarder is provided, and where air leakage occurs.

of an exterior insulated wall located

in a cold climate with no vapor barrier.

of an exterior insulated wall

located in a cold climate with

no vapor barrier and air leakage.